Diagrama del servoembrague

Jan 16, 2026

Diagrama del servoembrague

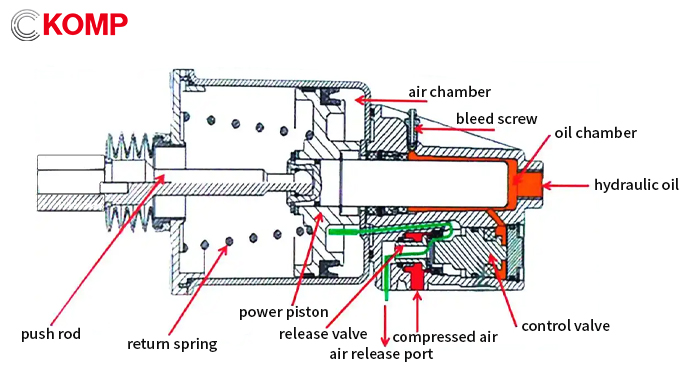

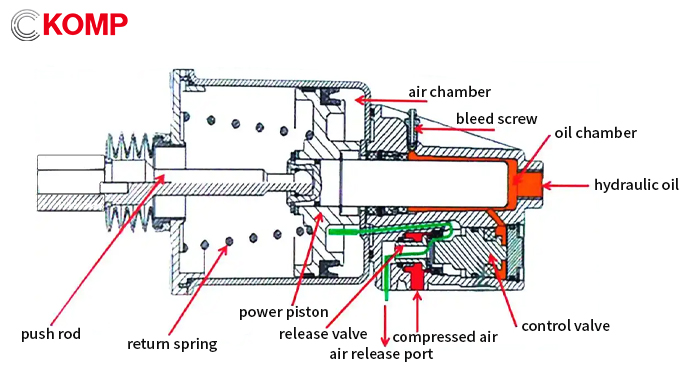

As a core auxiliary device in the transmission system of heavy-duty vehicles, the clutch booster plays a critical role in reducing pedal effort and improving shift smoothness. Its efficient pneumatic-hydraulic linkage operation depends on the precise coordination of multiple internal components. For

clutch booster manufacturers

, understanding the structural relationships and performance parameters of these parts is essential to ensuring durability, boosting efficiency, and long service life.

The air chamber and oil chamber form the foundation of the booster’s dual-cavity structure. The air chamber is designed to withstand pressures of at least 1.2 MPa and stores compressed air, while the oil chamber contains hydraulic fluid. A high-strength sealing partition separates the two chambers, preventing cross-leakage that could cause performance loss or failure. The inner surface of the oil chamber is precision-honed and phosphated to improve wear resistance and ensure smooth hydraulic oil circulation, allowing pneumatic and hydraulic systems to operate independently and reliably.

At the heart of the system is the power piston, which acts as the main force-executing component. It uses bidirectional piston rings to maintain effective sealing. During operation, the piston receives hydraulic pressure of approximately 0.8–1.0 MPa from the oil chamber and compressed air pressure of 0.6–0.8 MPa from the air chamber. The resulting pressure differential generates thrust that drives the push rod. To maintain clutch separation accuracy, the piston stroke error must be controlled within ±0.2 mm.

The push rod, manufactured from quenched and tempered steel, transfers force to the clutch release mechanism. Ball hinge joints at both ends reduce frictional losses, while a straightness tolerance of ≤0.1 mm/m ensures stable operation. Its working stroke typically matches the clutch release clearance of 8–12 mm, making it a key mechanical transmission link, especially in heavy-duty models such as the

clutch booster Isuzu

applications.

Air circuit control relies on the coordinated operation of the control valve and quick release valve. The control valve responds to hydraulic signals within 0.3 seconds, regulating compressed air flow, while the quick release valve rapidly exhausts air through a port of at least 8 mm in diameter. Together, they synchronize air pressure changes with pedal movement, ensuring fast and consistent response.

The return spring, made of high-strength alloy steel, restores the power piston and valve core to their initial positions when the pedal is released. A bleed screw located at the lowest point of the oil chamber removes trapped air from the hydraulic circuit, preventing air resistance. The system typically uses DOT 3 or DOT 4 brake fluid, valued for its wide temperature tolerance and stable anti-foaming properties—critical for the reliable operation of the

clutch servo cylinder

.

Through modular integration, these components form a complete operational chain: hydraulic triggering, pneumatic boosting, mechanical transmission, and rapid reset. This design delivers lighter clutch operation, smoother shifting, and represents the technical core of modern commercial vehicle transmission systems.

The air chamber and oil chamber form the foundation of the booster’s dual-cavity structure. The air chamber is designed to withstand pressures of at least 1.2 MPa and stores compressed air, while the oil chamber contains hydraulic fluid. A high-strength sealing partition separates the two chambers, preventing cross-leakage that could cause performance loss or failure. The inner surface of the oil chamber is precision-honed and phosphated to improve wear resistance and ensure smooth hydraulic oil circulation, allowing pneumatic and hydraulic systems to operate independently and reliably.

At the heart of the system is the power piston, which acts as the main force-executing component. It uses bidirectional piston rings to maintain effective sealing. During operation, the piston receives hydraulic pressure of approximately 0.8–1.0 MPa from the oil chamber and compressed air pressure of 0.6–0.8 MPa from the air chamber. The resulting pressure differential generates thrust that drives the push rod. To maintain clutch separation accuracy, the piston stroke error must be controlled within ±0.2 mm.

The push rod, manufactured from quenched and tempered steel, transfers force to the clutch release mechanism. Ball hinge joints at both ends reduce frictional losses, while a straightness tolerance of ≤0.1 mm/m ensures stable operation. Its working stroke typically matches the clutch release clearance of 8–12 mm, making it a key mechanical transmission link, especially in heavy-duty models such as the

clutch booster Isuzu

applications.

Air circuit control relies on the coordinated operation of the control valve and quick release valve. The control valve responds to hydraulic signals within 0.3 seconds, regulating compressed air flow, while the quick release valve rapidly exhausts air through a port of at least 8 mm in diameter. Together, they synchronize air pressure changes with pedal movement, ensuring fast and consistent response.

The return spring, made of high-strength alloy steel, restores the power piston and valve core to their initial positions when the pedal is released. A bleed screw located at the lowest point of the oil chamber removes trapped air from the hydraulic circuit, preventing air resistance. The system typically uses DOT 3 or DOT 4 brake fluid, valued for its wide temperature tolerance and stable anti-foaming properties—critical for the reliable operation of the

clutch servo cylinder

.

Through modular integration, these components form a complete operational chain: hydraulic triggering, pneumatic boosting, mechanical transmission, and rapid reset. This design delivers lighter clutch operation, smoother shifting, and represents the technical core of modern commercial vehicle transmission systems.